Individual housing SLA

“When smooth surfaces and transparent details create more than just a case – an experience of precision.”

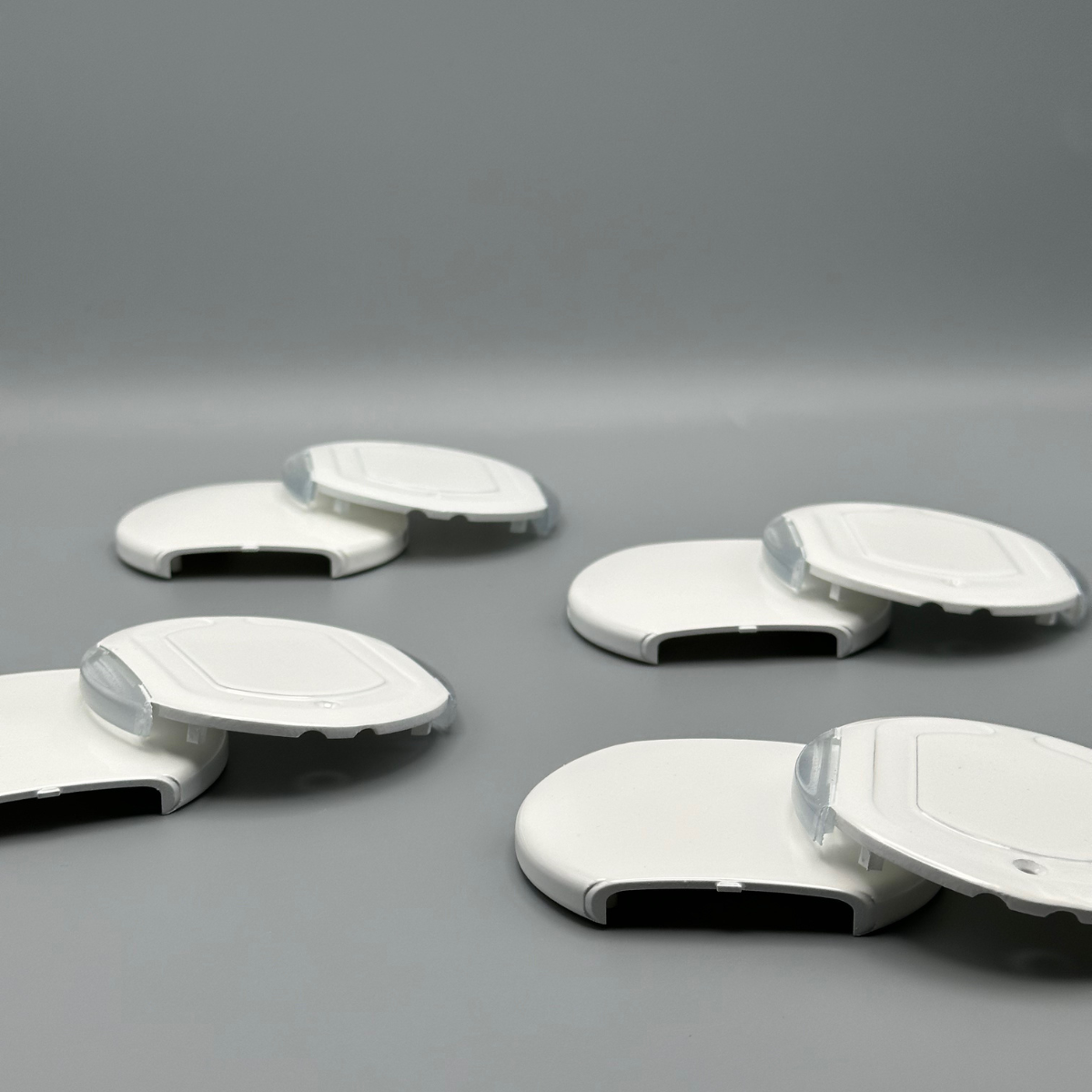

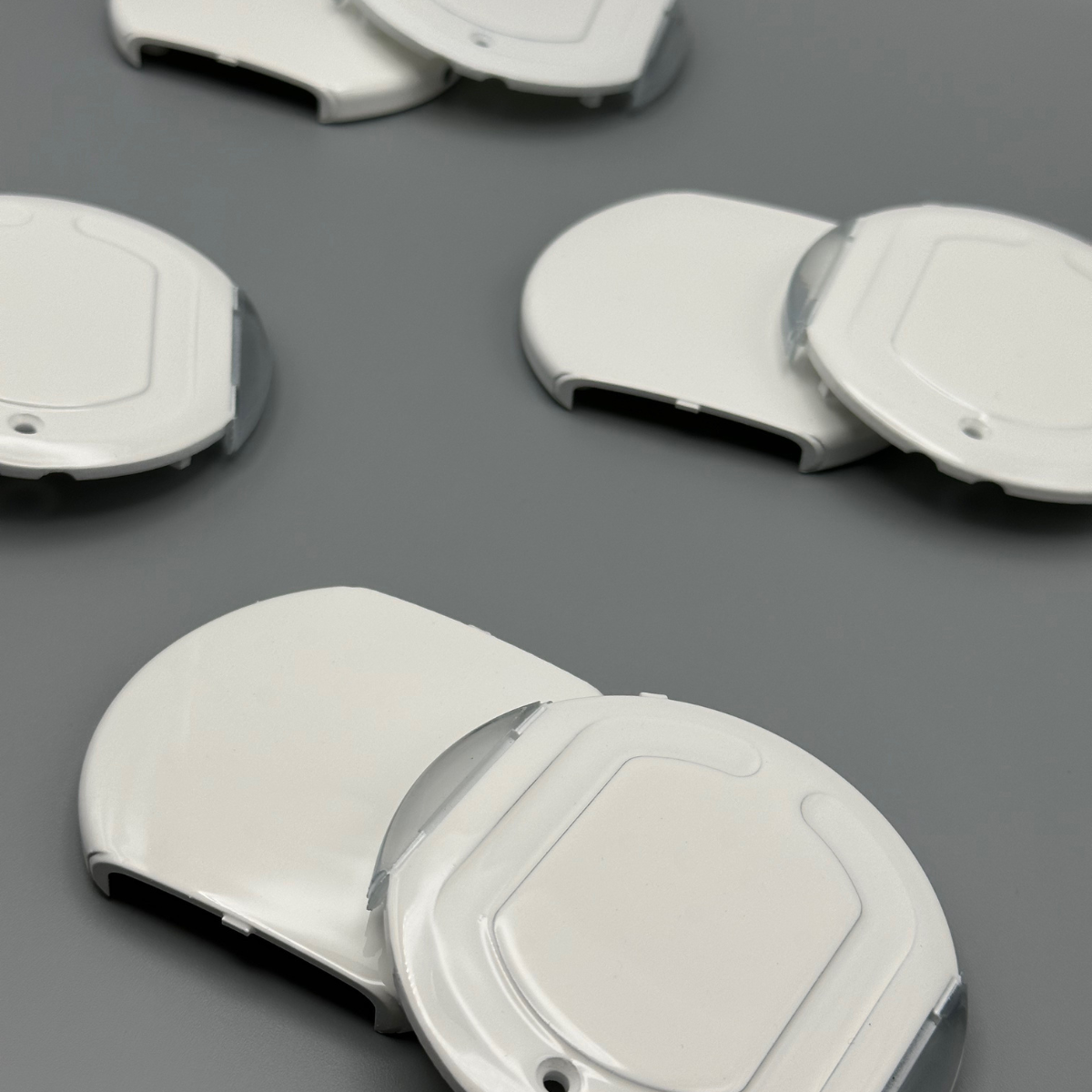

For the so-called vitalizer, a housing was to be created that was not only technically reliable but also visually outstanding. The requirements were demanding: high-gloss white, combined with transparent segments that allow a view of the interior, and the entire thing as a single, seamless component.

This is precisely where SLA 3D printing shows its strengths. Thanks to the particularly fine surfaces, we were able to manufacture the housing in such a way that the white areas could be painted perfectly, while the transparent segments retained their brilliance.

To ensure long-term quality, the process was thoroughly thought through. Flexible TPU elements protect the housing from scratches, and a specially designed base conceals the screw connections and ensures stability. The painting process also demanded precision: specially developed 3D-printed fixtures allowed the components to be processed in the booth from all directions. Additionally, the paint shop was equipped with ionized compressed air and a constant humidity of 45 percent to prevent dust and static charge.

The result is a custom SLA enclosure that combines functionality, design, and manufacturing expertise. The combination of SLA for the highest surface quality, TPU parts for protection, and FFF-printed fixtures for post-processing resulted in a product that not only looks unique but can also be mass-produced – with up to 40 units per week. This is how an idea becomes an enclosure that combines state-of-the-art technology with perfect aesthetics.