Surface finishing

"You can see what we do. You can feel it. And sometimes – it even shines."

With the new paint booth at MAKRA PRO, we have taken complete control over the surface, gloss level and finish.

Whether high gloss, satin or semi-matt – our components achieve not only technical but also visual excellence.

The project with BRABUS was the ideal opportunity to demonstrate these possibilities:

A component that is not only functional and precisely manufactured, but also showcases the full range of our surface finishing capabilities.

When BRABUS visited our new location in Schlüsselfeld for the first time, it quickly became clear:

We wanted more than just a gesture. We wanted to create something that reflects what drives us and what we're capable of.

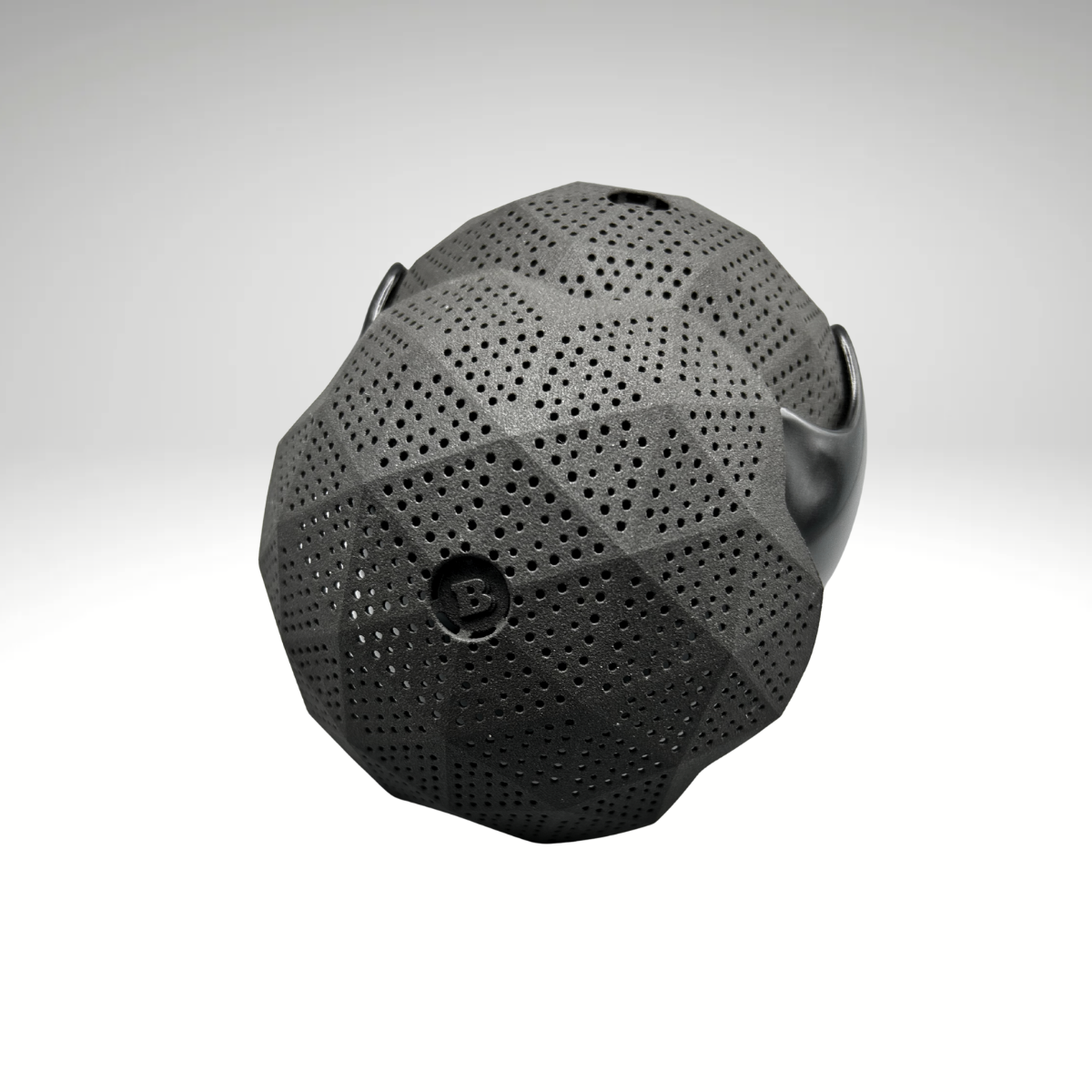

In just four days, a designer lamp was created that appears simple yet tells a story:

about material understanding, manufacturing expertise and finishing in 3D printing.

The idea: to make our strengths visible in a single component.

Not through mass or complexity, but through the precise combination of technology and aesthetics.

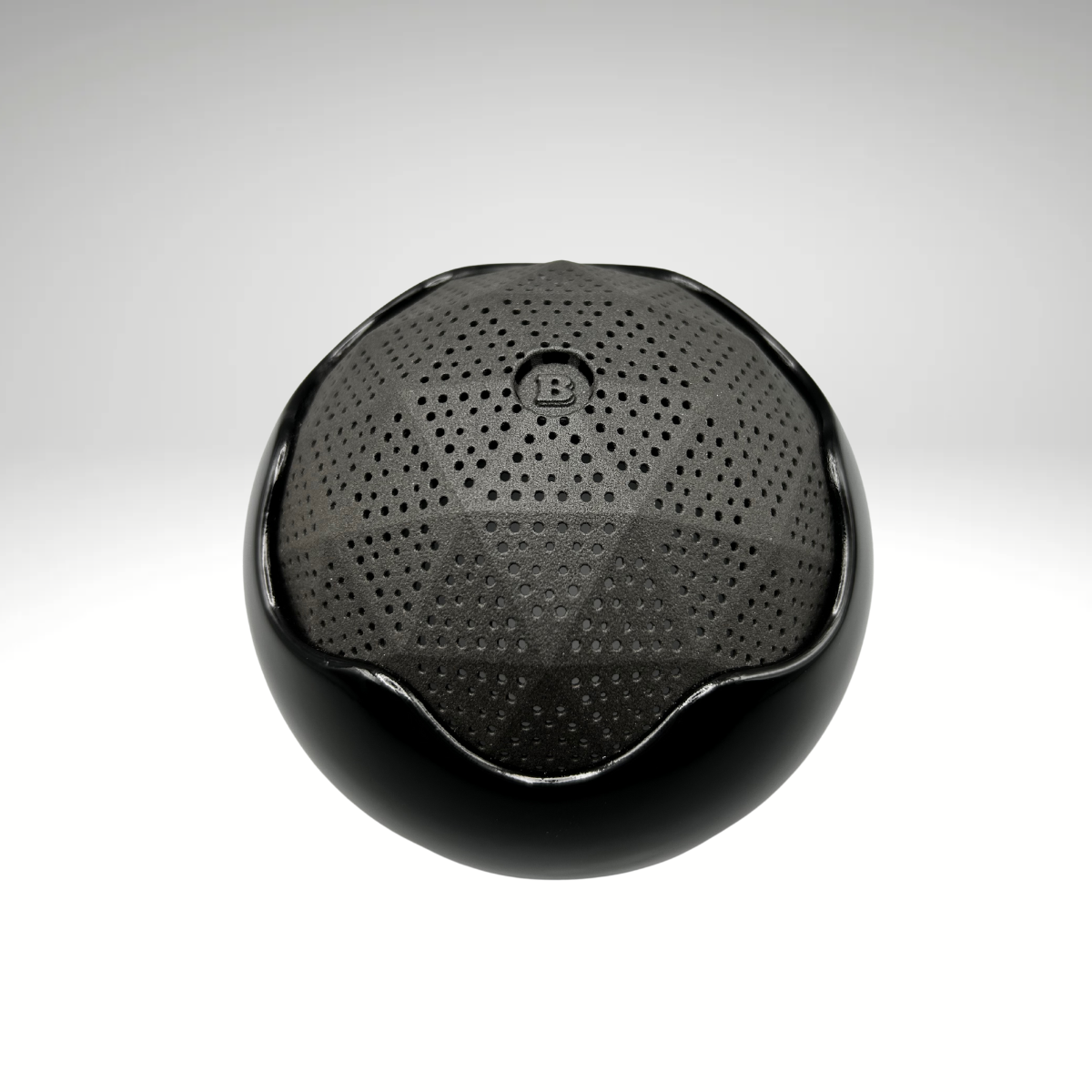

For this we used an iconic BRABUS pattern:

a perforated triangular structure that we interpreted three-dimensionally – inspired by mesh constructions, technically conceived, implemented with design ambition.

The component was manufactured using the SLS process , known for its strength and characteristically rough surface – a texture that we deliberately took into account in the design.

But that wasn't enough. Our goal was to demonstrate what's possible with post-production:

How a functional raw part is transformed into a high-quality design object.

We combined SLS, FFF and SLA – each technology with its own surface quality.

SLA provides smoothness, FFF and SLS bring structure – but no shine.

This is exactly where our surface finishing comes in.

The components were sanded, filled, sanded again, painted and finally finished with a clear coat in deep high-gloss black.

The application was carried out using a paint spray gun – with the craftsmanship and precision that is more familiar from vehicle paint than from additive manufacturing.

The result is a surface that respects the original structure while creating new visual depth.

The combination of a refined feel and a reflective finish creates a contrast that appears luxurious and highlights the refinement capabilities of our production.

Not a series product – but symbolic of what we do:

Turning raw forms into character.

Because surface is not a compromise, but design.